Who We Are • What We Do

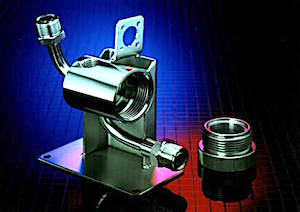

Precision Machining, Fabrications, Assemblies

Steel (carbon & alloy), Stainless (nickel alloys), Aluminum, Copper & Brass & Bronze, Rubber (Neoprene), Plastic (PVC, Nylon, Delrin, UHMW, Teflon), Fiberglas, Glastic, etc.

Food Processing, Air/ Water Filtration, Rail Transportation, Bio-Medical, Marine/Oceaneering, Defense/Military, Optics/Microscopes, Telecommunications, Electronics, etc.

- BRIDGEPORT, GX 1000 (40″ x 21″ x 21″){NEW} Vertical Machining Center (X,Y,Z), configured with three guideways and five guide trucks on both the X- and Y-axis; two guideways and six guide trucks on the Z-axis.

- OKUMA, MC-V 3016, 30” x 16” with Indexer, High Pressure Coolant & Chip Conveyor.

- BRIDGEPORT, GX 1600, 27 ½” x 63” Travel, High pressure coolant, with indexer.

- OKUMA, Millac 44 Horizontal Milling Center, 15” x 18” x 16” Travel, with pallet changer.

- BRIDGEPORT, Milling Machines (2), Power Travel.

- OKUMA, L370 MW Twin Spindle with live tooling and bar feed, 2 3/4” thru Spindle.

- OKUMA, ES-L8 with bar feed, 1 5/8” thru Spindle, 8” Swing.

- OKUMA, LB-12 with bar feed, 1 5/8” thru Spindle, 8” Swing.

- METHODS, Slant 50C, 2 ½” thru Spindle, 10” Swing.

- HARRISON, Alpha-460T, 16” Swing, 6 Ft. Bed.

- HARDINGE, Second Operation Lathe with Turret

- CLAUSING, 14” Lathe

· TRUMPF Trumark Station 5000-Laser Part Marking

- One Full Time Quality Control Inspector

- DELTONIC, DH 14 Optical Comparator

- FOWLER SYLAS, Electronic Height gage

- BROWN & SHARP, Profilometer –Roughness Gage

- STARRETT, Granite Surface Plate-Grade-A-Inspection, 18” x 24”

- FOWLER, Dial Bore Gage- 1.4” to 6”

- Chamfer Gage Set

- SWIFT, Inspection Microscope

- All Standard Micrometers(0” – 10” Calibrated)

- All Standard Thread Rings and Thread Plugs –Certified

- VERMONT, Gage Pins- .011’ thru 1.00”

About Us

We invest in people, equipment and systems that enable us to deliver high quality, complex, precision machining and fabrications from prototype thru production with on time deliveries. These on-going relationships are enhanced by fair dealing, superior communications, a knowledgeable work force and employing state-of-the-art technologies, equipment, and processes.

We manufacture in-house but will seek professional goods, services, and advise from other sources in order to best satisfy our customers’ requirements and needs. Some of the Industries we are currently serving are: Telecommunications, Air & Water Filtration Systems, Food Processing Machinery and Rail Transportation.

Solving problems since 1969

We Provide Precision Machine Shop Services in Massachusetts

Precision Machining

Extensive knowledge and expertise in all facets of vehicle, commercial and residential areas.